Acrylic sheets are a versatile choice for various projects, from crafting to industrial applications. Understanding how to cut acrylic effectively opens up endless possibilities for creativity and innovation.

In this guide, we'll go over various methods for cutting acrylic sheets, with a focus on laser cutting. We’ll also go over some other methods like using a jigsaw, scoring knife, table saw, band saw, and router cutting.

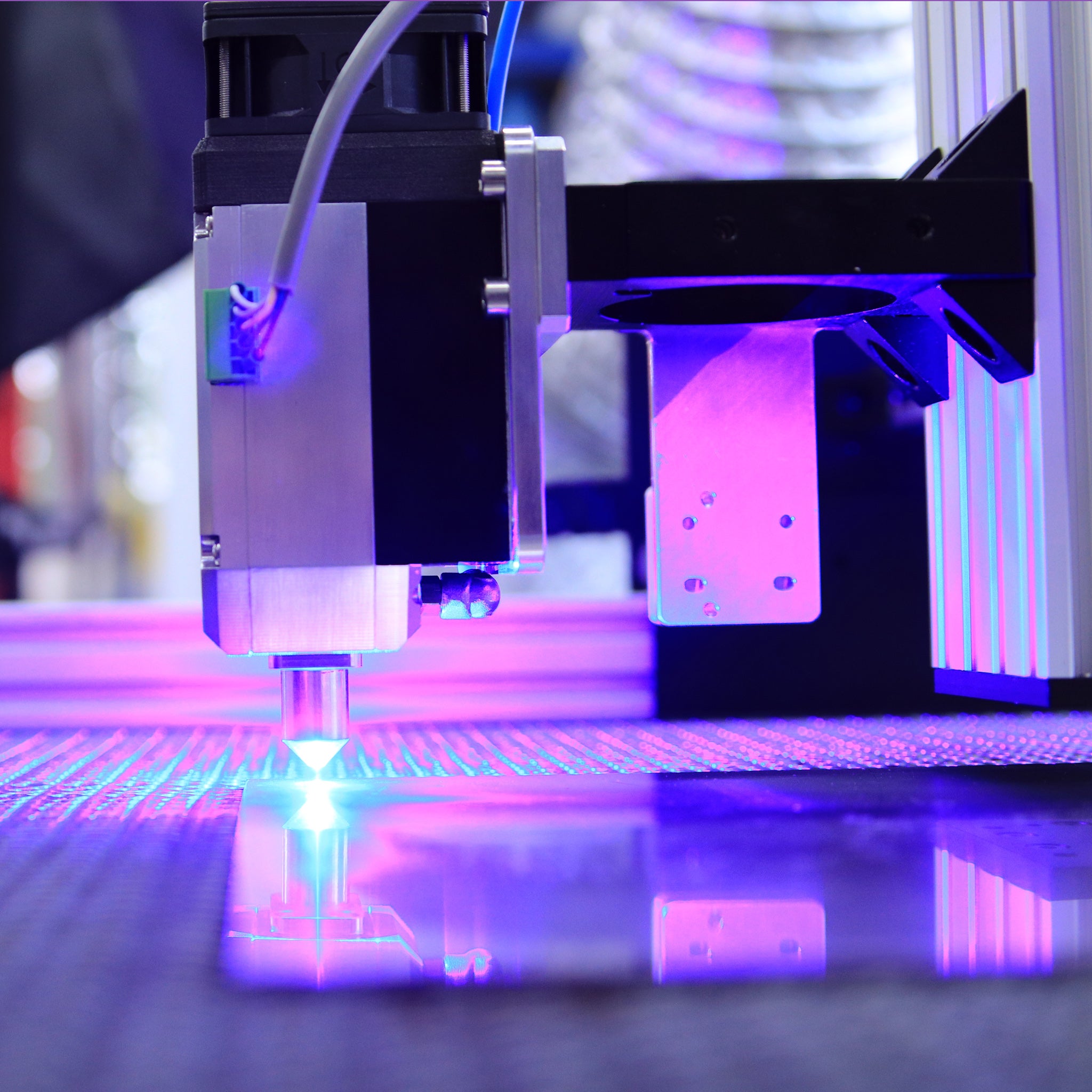

Laser Cutting Acrylic

Laser cutting stands out for its precision and versatility, making it a preferred choice for designers and craftsmen. By directing a concentrated beam of light at the acrylic sheet, the material is melted and vaporized along the desired path, facilitating the creation of intricate designs and impeccably clean cuts.

CO2 lasers are known for their effectiveness, slicing through a diverse array of colors and thicknesses of acrylic. This adaptability ensures that regardless of the project's requirements, there's a laser-cutting solution available. When selecting acrylic for your project, it's important to consider both the color and thickness of the material.

While CO2 lasers excel at cutting acrylics of any color, like these clear glitter acrylic sheets, diode lasers can be limited to cutting darker, opaque acrylics, like this black cast acrylic. The thickness of the acrylic plays a significant role as well; a 20W diode laser, for example, can efficiently cut acrylic up to 3mm thick. CO2 lasers, with their higher power, can handle most commonly available acrylic sheets with ease, making them suitable for a wide range of applications.

Laser cutting is ideal for achieving smooth edges and complex shapes. It also offers unparalleled accuracy, allowing for the precise replication of designs with minimal material waste.

The non-contact nature of this method eliminates the risk of mechanical stress, preventing cracking or chipping of the material. This ensures that each piece maintains its aesthetic appeal and structural integrity, making laser cutting a superior choice for projects that demand the highest standards of quality and precision.

Benefits of Laser Cutting:

- High precision and control

- Clean, smooth edges

- Versatility in cutting complex shapes

- No physical stress on the acrylic, minimizing cracks

Jigsaw Cutting

For projects requiring curved cuts, a jigsaw is a suitable choice. It's important to use a sharp fine-pitch blade and proceed slowly to prevent melting or chipping. Masking the cutting area can help protect the acrylic surface from scratches.

Jigsaw Cutting Tips:

- Use a fine-pitch blade

- Cut slowly to minimize heat

- Mask the surface to avoid scratches

Scoring Knife

A scoring knife can effectively cut straight lines or gentle curves in acrylic sheets. This method involves scoring the surface with a sharp blade and then snapping the acrylic along the scored line. It's a simple technique ideal for thinner sheets.

Best Practices for Scoring:

- Wear protective gloves and eyewear

- Use a straight edge for precise scoring

- Apply consistent pressure for a clean scoreline

- Snap the acrylic over a table edge for a clean break

Table Saw and Band Saw

Both table and band saws are effective for making straight cuts, with table saws being particularly good for large sheets. Using a fine-pitch blade and keeping the speed low to reduce heat is crucial. Masking the surface can prevent scratches, and supporting the material properly will avoid chipping.

Saw Cutting Advice:

- Use a fine-tooth blade for smooth cuts

- Keep the material well-supported

- Cut slowly to control heat generation

Router

Routers offer flexibility for both curved and straight cuts. Pre-cutting the acrylic with another tool and finishing with a router can achieve precise edges. Using a bit that matches your cutting needs, such as upcut or downcut bits, will influence the quality of the cut.

Router Cutting Tips:

- Use a compressor to keep the acrylic in place

- Choose the right bit for your specific cut type

- Pre-cut the acrylic for best results

Finishing Your Cut

Regardless of the cutting method chosen, the finishing touches you apply to the edges of your acrylic pieces can significantly improve the final appearance and tactile feel of your project. Sanding, polishing, or employing flame polishing methods are effective ways to achieve a smooth, clear edge, thereby elevating the overall quality of your work.

When sanding, begin with a coarser grit sandpaper to quickly remove any roughness, gradually transitioning to finer grits to achieve a smooth finish. For a glossy, transparent edge, polishing with a specialized acrylic polish can make a big difference, rendering the edges not smooth and visually appealing.

Flame polishing can provide a remarkably clear finish by carefully passing a flame over the edge, melting the surface just enough to make it shine. It’s important to approach this method with caution, as overheating can cause the acrylic to warp or discolor.

Whichever method you choose, taking the time to properly finish the cut edges of your acrylic pieces can transform a good project into a great one, reflecting the care, skill, and attention to detail you've invested in your work.

Final Thoughts

Whether you're utilizing the precision of laser cutting, the versatility of a jigsaw, or the simplicity of a scoring knife, Learning how to cut acrylic is just the beginning.

With COHn Acrylics, you're not just purchasing materials; you're joining a community dedicated to quality, creativity, and support. Whether you're starting your journey in laser cutting or looking to improve your business, COHn Acrylics offers the products and guidance to ensure your projects shine.

Remember, safety first. Always follow the manufacturer's guidelines for your tools and wear appropriate safety gear.

For more tips, inspiration, and to explore our range of acrylic sheets, visit us at www.cohnacrylics.com.